Ball vs. Sleeve: A Comparison in Bearing Performance

As consumers demand smaller, faster computer systems, OEM design engineers race to create systems with compact, more powerful microprocessors and chipsets. However, these compressed designs provide engineers with a new enemy…heat. In minutes, densely packaged microprocessors or compact electronic systems can generate enough heat to destroy years worth of work.

A design engineer needs a reliable fan that will maintain system cooling and protect against system meltdown. Most engineers believe that a quality axial fan is an answer to this threat. Yet, many engineers debate over which bearing to use in the axial fan. Since bearing type is a crucial factor in determining an axial fan’s reliability, it is important that the design engineer choose the right bearing for the right application.

The Criteria

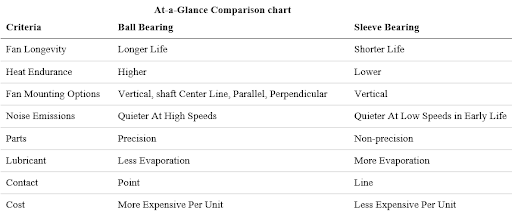

There are two main types of bearings that are used in axial fans: ball and sleeve bearings. When choosing between a ball bearing and a sleeve bearing fan, the engineer must consider:

⦁ Fan Longevity

⦁ Mounting

⦁ Noise

⦁ Parts

⦁ Lubrication Issues

⦁ Line vs. Point Contact

⦁ Cost

(See At-a-Glance Comparison chart below)

Fan Longevity

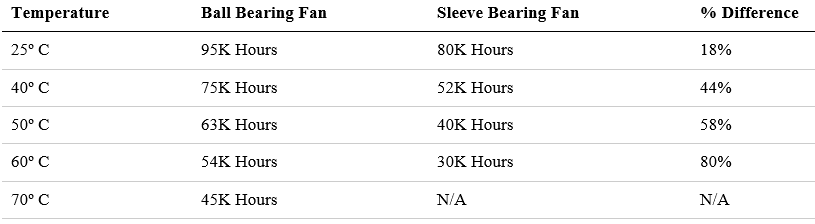

Since fan reliability is the most critical factor in fan performance, it is important that a fan-run consistently for a number of years. The following chart uses the L10 method to illustrate fan performance at various temperatures. L10 refers to the point of time at which 90 percent of a large population of these fan types will continue to work. On average, a fan that operates for 50,000 hours will run continuously for over 5 years.

The chart indicates that when temperatures range from 25º- 60º C, ball bearing fans on average outlasted sleeve bearing fans by 50 percent. When temperatures exceeded 70° C, ball bearing fans ran for 45,000 hours, while sleeve bearing fans became inoperable. Yet, when the ambient temperatures were relatively low, sleeve bearing fans lasted as long as ball-bearing fans. Therefore, if an application generates high levels of heat, an engineer may want to use a ball bearing fan. If the equipment generates low heat intensities, or if the equipment has a short life span, the design engineer may want to use a sleeve bearing fan.

Fan Mounting

Another factor that can impact fan longevity is fan mounting. Fans can be positioned horizontally, or shaft centerline parallel, or perpendicular to the ground. Fan orientation does not affect the longevity of ball bearing fans. Ball-bearing fans can be mounted in any position because preloading of the bearings is built-in during the bearing manufacturing stage. Preloading describes the procedure by which manufacturers build an initial side load, such as a spring or a wave washer against the balls, into the ball bearing.

This makes the bearing more durable. In comparison, sleeve bearing fans can maintain life spans comparable to their ball bearing counterparts when the sleeve bearing fans are mounted in vertical positions. However, when sleeve bearing fans are mounted in any position other than vertical, the fan’s life span decreases. When selecting a bearing type, the design engineer must consider the orientation for which the fan will be mounted. If the fan needs to be mounted vertically, the engineer might choose a sleeve bearing fan. However, if the fan is mounted in any orientation other than vertical, the engineer may want to select a ball bearing fan.

Noise

In many office environments, noise is a primary consideration for selecting office equipment. The faster a fan runs the more noise it will generate. While Americans have become acclimated to hum of the HVAC and computer equipment, many European offices have not. Therefore, many European offices need office equipment that produces minimal noise. In the past, design engineers assumed that sleeve bearing fans ran more quietly than ball bearing fans. This is true for applications that have very low fan speeds. Yet with innovations in preloading, ball bearing fans can work as quietly as a sleeve bearing fans, especially in applications that require faster fan velocities. With their machine-controlled parts, preloaded ball bearing fans have exact tolerances that can minimize fan noise. For sleeve bearing fans, fan noise depends on the clearance of the fan’s bushing. The level of the noise generated will vary with the variance in the component parts.

Parts

The manufacturing process for ball bearings and sleeve bearings are fundamentally different, resulting in a significant difference in the part precision level. Typically, sleeve bearings deteriorate under high temperatures because they are made from porous, powered metals in a sintering process. Also, sleeve bearing fans can develop a high micro-hardness that makes secondary machining difficult. Steel parts make ball bearing fans more exact. They are precision ground and super finished. If an engineer is seeking precision parts, ball bearings are the right choice. If an engineer does not need precision parts, sleeve bearings are an alternative.

Lubrication Issues

In a computer system, bearing lubrication failure will cause axial fan failure. Axial fan failure can lead to system failure. To reduce friction and minimize overheating, axial fans need lubrication. Lubricants need to withstand the weight of fan assembly, thrust and rotor assembly imbalance. If the lubricant evaporates, the system can be destroyed. Sealed-for-life ball bearing systems use thicker lubricants that have more additives, and are less subject to evaporation. While the lubricants within sleeve bearing fans have a greater concentration of oil, the sleeve bearings’ bushings can only hold a fixed amount of lubricant. Since there is no periodic recharging of the oil, the lubrication within a sleeve bearing system is more likely to evaporate.

Point of Contact

As stated earlier, friction will cause failure in axial fans. In addition to the amount of lubricant, the point of contact also dictates the amount of friction an axial fan sustains. The more friction a bearing sustains, the greater the likelihood for axial fan failure. Sleeve bearings are line contact bearings; therefore, there is broad contact between shaft and bearing during the back-and-forth sliding motion. This system generates a good deal of friction. Ball bearings are point contact bearings, which generate minimal friction. Previously, opponents of ball bearing fans argued that the ball bearing system could lead to brinelling or indentations in the raceway. Yet defenders of the ball bearing system believe that if a ball bearing system is assembled correctly, each component will fit together perfectly eliminating the potential for parts damage.

Cost Considerations

When purchased in large quantities, per unit, sleeve bearings are less expensive. Yet, ball bearings have greater life spans and over time provide greater value per dollar.

Summary

In conclusion, if an engineer is designing a computer system that has a short life span, or a system that will not generate high levels of heat, the engineer may want to select a sleeve bearing fan. However, if the application is a fast, densely packed microprocessor, or a compact electronic system, the engineer may want to choose a ball bearing fan that will endure hotter temperatures, have a greater life span and ultimately provide a greater long term investment.

NMB Technologies Corporation is a MinebeaMitsumi Group company; the world’s largest manufacturer of NMB miniature ball bearings and a volume leader in the design and manufacturing of precision electro-mechanical components, backlight and LED lighting products and advanced technology solutions for smart cities, medical automotive and industrial markets.

NMB Technologies Corporation

A MinebeaMitsumi Group Company

39830 Grand River Avenue

Novi, MI 48375

USA

Tel: 248-919-2250

Email: info@nmbtc.com

Web: nmbtc.com